Supplier Relationship Management Software

Purpose-Built for Complex Procurement & Materials Management

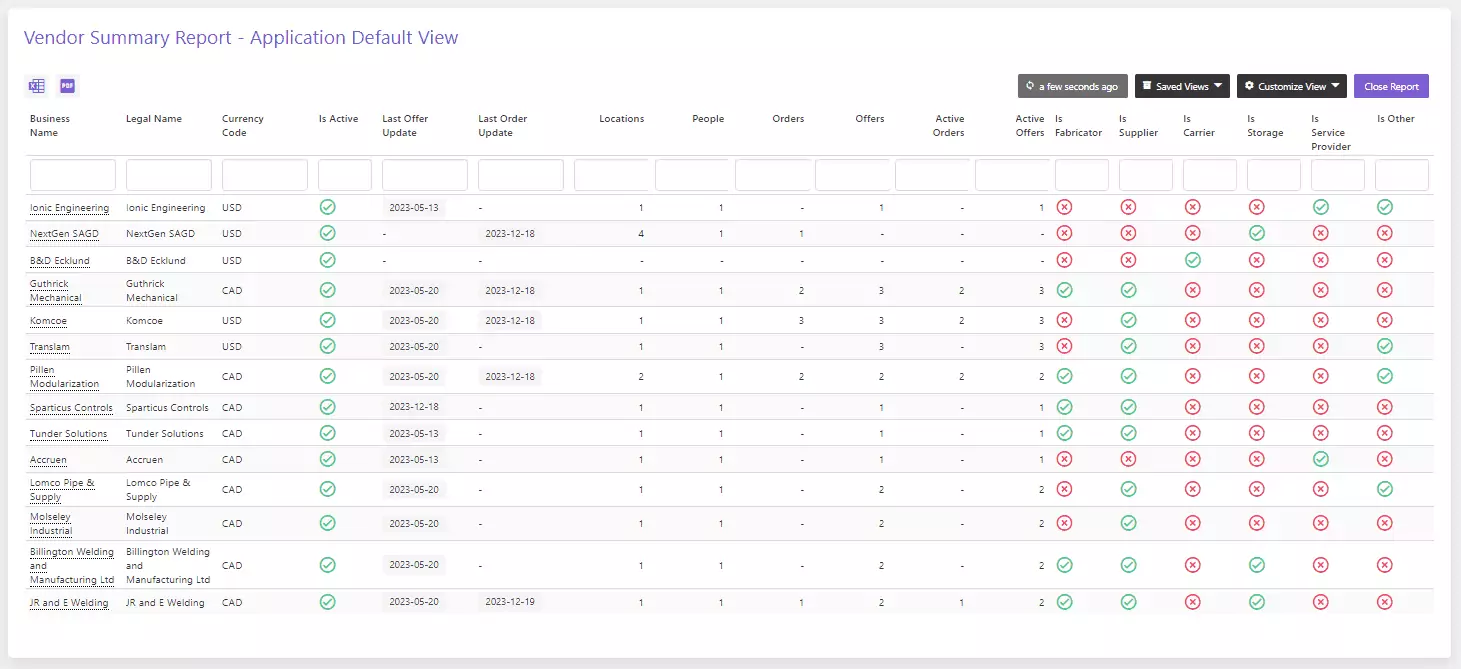

Efficiently maintain records of all key suppliers, including essential details such as key contacts, locations, approved projects, preferred terms, and complete bid and order history.

Manage supplier performance by tracking supplier KPI metrics, creating custom supplier performance evaluations, and leveraging qualitative supplier performance ratings.

Mitigate supplier-related risks through integrated Vendor Document Requirements, automated supplier non-conformance reporting, and various supplier performance management tools.

Supplier Relationship Management for Complex Procurement

Streamline Supplier Enrollment, Engagement and Evaluation

Unlock the full potential of your supplier relationships with our supplier relationship management tools.

Seamlessly oversee and monitor supplier relationships. Empower your team with accessible supplier information to maximize and strengthen your supplier relationships. Track supplier performance, measure vendor compliance against the terms and conditions of your contract, and identify areas for vendor improvement. Optimize the supplier performance evaluation process, enable informed decisions regarding ideal suppliers, and build resilient and sustainable supplier relationships through our comprehensive supplier management tools.

Efficient Supplier Relationship Management Through Categorization & Customization

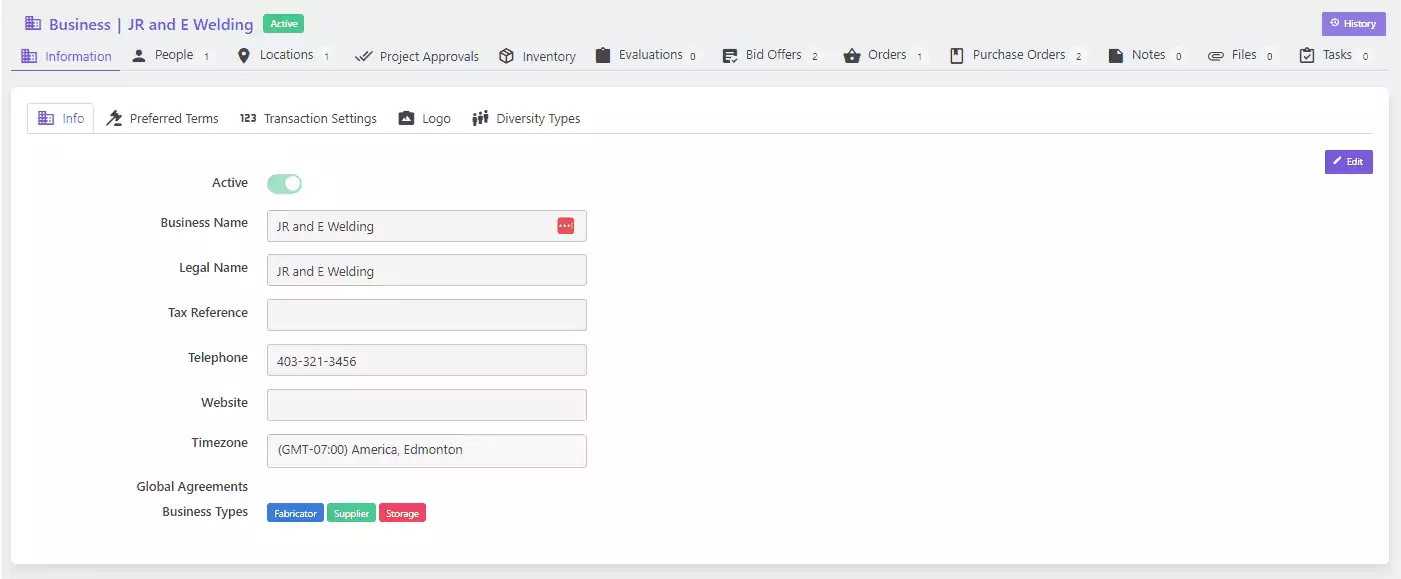

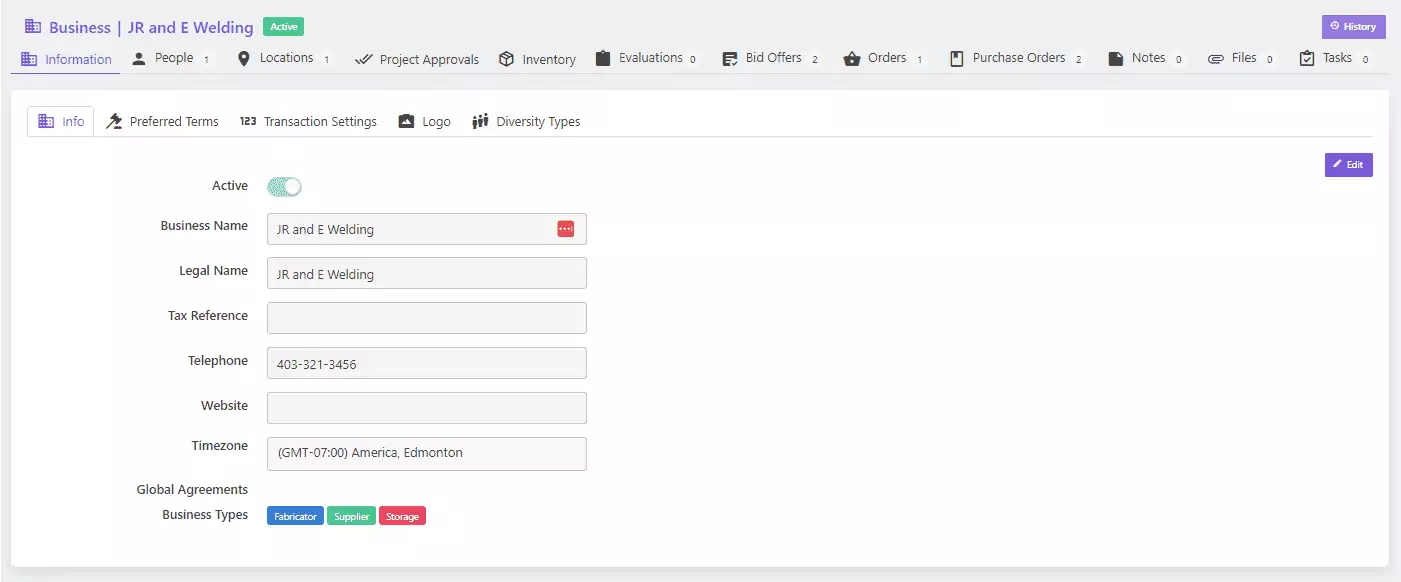

For efficient supplier management, categorize vendors under one or more business types, including Supplier, Fabricator, Carrier, Storage, and Service Provider. Add custom specialties to each vendor to allow for further categorization. Create custom supplier diversity types and tag relevant vendors. Customize each supplier by adding supplier-specific currency, default tax, payment terms, IncoTerms, document numbering configuration, business transaction settings, business transaction rules, and more!

Supplier Relationship Management Key Features

Centralized Supplier Information Management

- Maintain records of all key suppliers, including essential details such as core company information, key contacts, locations & location type, time zone, company logo, approved projects, global agreements/contracts, preferred terms, and more!

- Complete transaction history, including every Bid and every Order.

- Cloud-based supplier information accessible from anywhere, at any time, on any device with an internet connection.

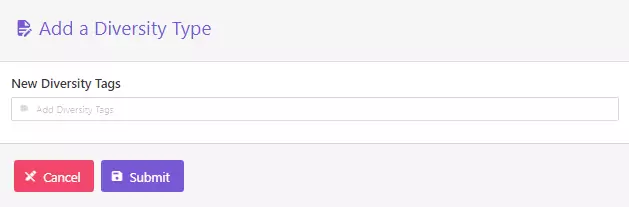

Supplier Diversity Tracking

- Current SCM supports the delivery of Environmental, Social, and Governance (ESG) objectives with built-in supplier diversity tracking.

- Create custom supplier diversity types in alignment with your ESG objectives.

- Generate automatic reports of bidding history by supplier diversity type and purchase value by supplier diversity type.

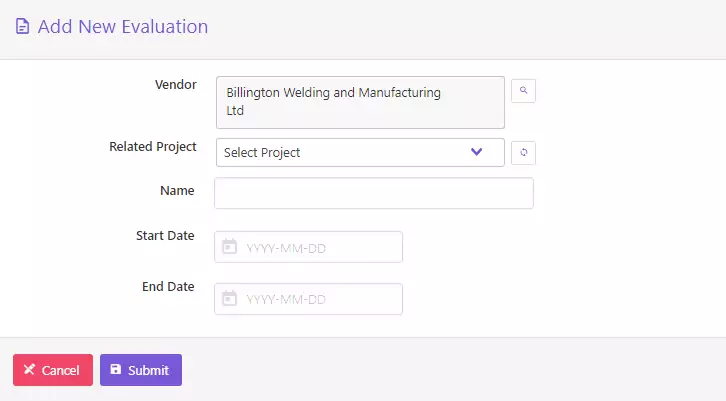

Streamlined Supplier Performance Management

- Evaluate supplier performance within a data-driven and transparent supplier evaluation system that simplifies the evaluation process:

- Customizable supplier evaluation templates

- Project or Order-centric assessments

- Track Orders, timelines, compliance, delivery quality, and other supplier performance management KPIs.

- Manage, monitor, and optimize supplier performance with qualitative supplier performance rating.

Supplier Risk Management

- Track all issues of supplier non-conformance with automated non-conformance reporting.

- Identify and mitigate supplier-related risks through supplier performance analysis and supplier performance rating.

- Give decision-makers across the company insight at the point of decision to buy from ideal suppliers.

Supplier Relationship Management Highlights

- Centralized Supplier Information Management

- Supplier Categorization

- Supplier-Specific Contacts

- Supplier-Specific Locations

- Supplier-Specific Contracts

- Supplier-Specific Currency

- Supplier-Specific Default Tax

- Supplier-Specific Payment Terms

- Supplier-Specific IncoTerms

- Supplier-Specific Business Transaction Settings

- Supplier-Specific Business Transaction Rules

- Supplier-Specific Bid History

- Supplier-Specific Order History

- Project-Specific Approved Suppliers

- Integrated Vendor Document Requirements

- Vendor Document Expediting

- Vendor Document Submission Tracking

- Supplier Bid Import Templates

- Supplier Diversity Tracking

- Supplier Performance Management

- Supplier Performance Analytics

- Supplier Performance Management

- Customizable Supplier Evaluations

- Project-Specific Supplier Evaluations

- Order-Centric Supplier Evaluations

- Supplier Non-Conformance Reporting (NCR)

- Supplier Risk Management