Turbo-Charge your Centralized Purchasing

Current SCM has launched a very exciting new feature that will provide even greater flexibility for our users. Cross-Project Inventory Transfers allows users to execute inventory movements between projects by locating inventory and includes the transfer of financial transactions in just a few clicks.

Where would you use Cross-Project Inventory Transfers?

In our flexible execution model, the default “holder” of inventory is the Project (don’t sweat, this can be customized, and we have seen organizations use ‘Job’, ‘Branch’, ‘Division’, etc…). The application tracks inventory controlled by each Project, along with the associated costs. This allows for project centric procurement, including project specific financials and inventory reporting. This focus works fantastically, providing native support for job/project costing, particularly in the EPC Procurement model.

However, the team collectively saw potential for other types of execution models with the ability to move inventory, with the associated financials, between two projects (or two jobs, or two divisions). This would facilitate full support for:

- Centralized Purchasing – Materials, particularly bulks, can be purchased with the intention of being issued to many projects (jobs).

- Surplus – Other organizations continue to purchase on a per-job basis, but require means to track, store, and then further issue the surplus materials if the project requirements shift during execution, or if the project is cancelled or deferred.

- Advanced Material Expediting – Allow users to transfer items on a one off basis to meet a more urgent material requirement in another project, whilst ensuring all of the financials impacts are perfectly captured.

Cross-Project Inventory Transfer Process

- Draft the transfer, select the providing and receiving project. Select items within inventory holding locations, and add to the transfer.

- Complete review and approval stages.

- System then executes the transfer in the Inventory ledger, and creates offsetting Purchase Order (in the receiving project), and Sales Order (in the providing project).

- Done and done.

Locating and Valuing Inventory

Current SCM has great tooling to locate inventory of specific items across all of a teams inventory locations. In addition, with this new feature, we have launched additional tools to locate, and get summary pricing information in one place. This makes transfer pricing setting a breeze.

Select either the average price of the inventory, the last price paid for that item, or manually configure the transfer pricing, which ever matches your internal policies.

Clear and Auditable Transactions

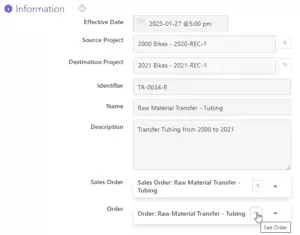

Upon approval, Current SCM takes care of the heavy lifting and creates two offsetting financial transactions: a Purchase Order to recognize costs in the receiving project, and a Sales Order to recognize revenue in the providing project. These transactions are available to dive into just like your other transactions.

Just like other inventory transactions, you will see a clear entry in the inventory transaction ledger to show the movement. The receiving project will show a Transfer In and the providing project a Transfer Out

The Current SCM team is really excited to get this functionality into the hands of our users. We feel the ability to easily, and rapidly transfer inventory between jobs will further enhance Current SCM as the best procurement system for project based organizations.

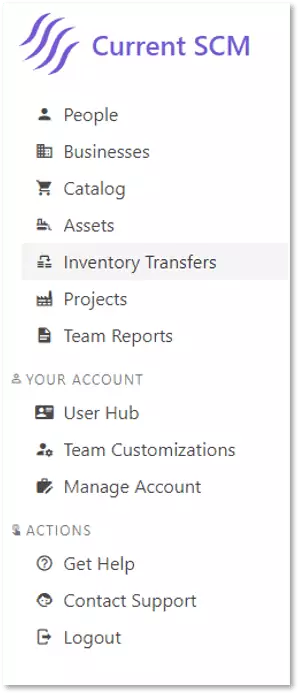

Engaged in Complex Procurement?

Current SCM is a cloud-based software that streamlines the process of project-based procurement & materials management and drives collaboration among project stakeholders. The term “project” can be defined as a construction project or a manufacturing project, or it can simply represent the way a business organizes their procurement (e.g., by project, program, product, client, division, business unit, region).

Current SCM offers a unique platform to manage the end-to-end process of project-driven supply chain management, including support for the planning, procurement, and management of both materials and services. Current SCM includes a robust set of project-based toolsets, including Project Planning, Material Planning, Service Planning, Vendor Document Requirements Management, Requisition Management, Bid Management, Purchase Order Management, Service Order Management, Material & Document Tracking, Inspection Management, Vendor Invoice Matching, Project Inventory Management, Project Asset Management, and more!

And Current SCM excels in accommodating diverse project requirements with unrivaled flexibility & control, including project-specific User access & permissions, cost structures, business rules, approved vendors, workflows, terms, reports, and much, much more!

If you engage in any of Project Procurement, Technical Procurement, Direct Procurement, or Third Party Procurement, Current SCM will optimize your procurement & materials management workflow. If you engage in all four, Current SCM will revolutionize the way you do business.

Contact the team at Current SCM today to learn more!