Materials Management Software

Purpose-Built for Complex Procurement

Complete and flexible workflow support to efficiently manage materials through Planning, Purchasing, Allocating, Tracking, Expediting, Releasing, Inspecting, and Receiving.

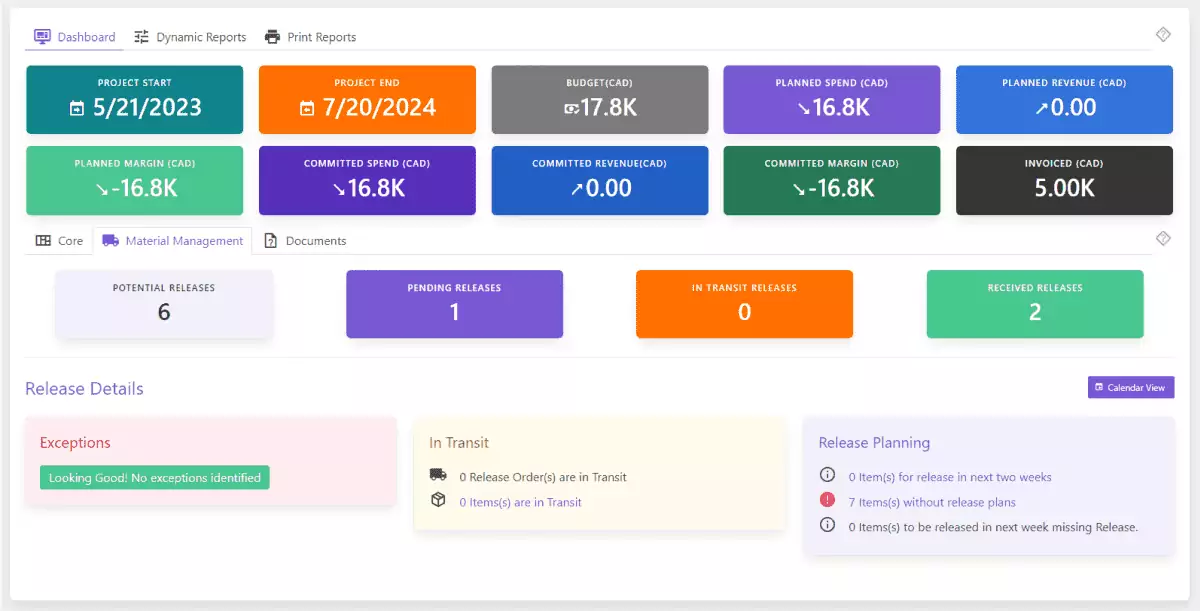

With Materials Management uniquely integrated into the Purchase Order, Current SCM provides a unified platform to both Purchase and Manage materials for your Projects.

No more waiting for reports or stale information. Real-time Order status updates and real-time Order line-level status updates to support milestone-driven materials expediting.

Cloud-Based, Project-Driven Materials Management Software

A Unified Platform for the End-to-End Process of Project-Based Materials Management

With Materials Management and Vendor Document Requirements (VDR) uniquely integrated into the Purchase Order, Current SCM provides a seamless platform to Purchase and Manage materials for Projects. A unified, collaborative platform for Buyers and Expeditors, Current SCM provides complete and flexible workflow support to efficiently manage material through Planning, Purchasing, Allocating, Tracking, Expediting, Inspecting, Releasing, and Receiving. Our project-based materials management software also includes support for Material Inventory Management and Asset Management.

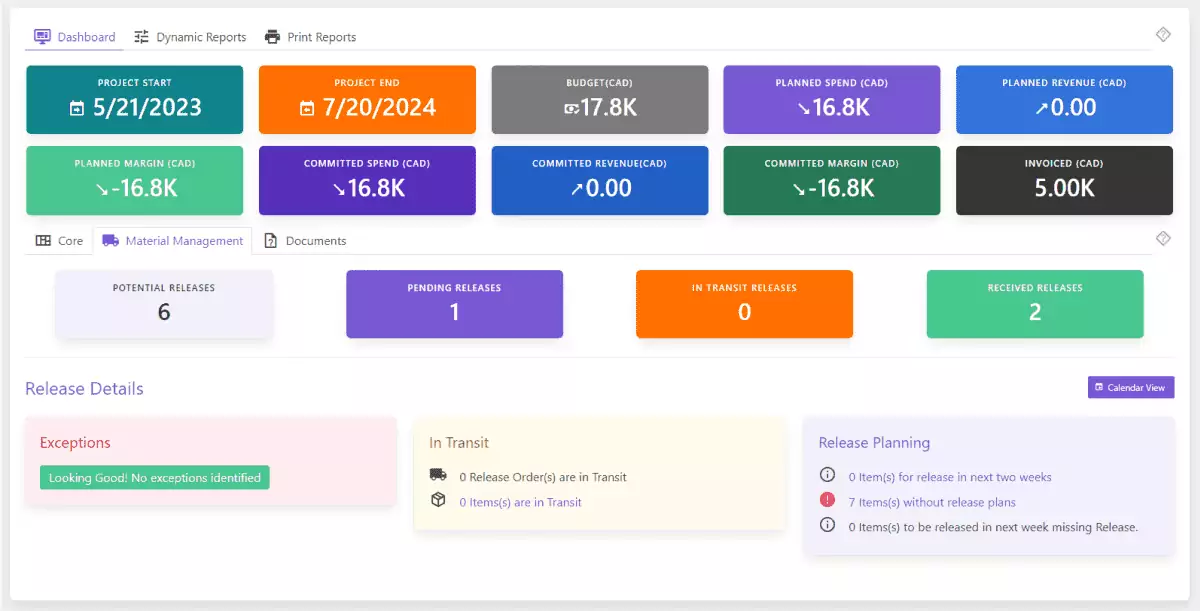

Real-Time Insights into Materials in Constant Motion

Whether your fulfillment strategy is to procure, draw from existing inventory, or a mixture of both, Current SCM can help. Leverage real-time material inventory availability reporting by Location, Business, or Project (including current inventory, allocated inventory, inventory available for allocation, and inventory quantity incoming) to ensure you are optimizing inventory and purchasing only what you require. When procurement is required, leverage powerful Purchase Order line-level status updates for milestone-driven Expediting to monitor delivery schedules and proactively identify any material delays or shortages. And whether coming from inventory or a supplier, plan and execute the movement, storage, and consumption of your materials between locations – from suppliers to storage facilities to fabricators to construction sites and more!

Ensure you receive the right materials at the right time in the right quantities at the right cost from the right sources.

Materials Management Key Features

Material Requirements Planning (MRP)

Current SCM supports Material Requirements Planning in a variety of ways, including:

- Specifications & Standard Drawings: Define the specifications and standard drawings templates for your organization, for a client, or for a specific project. Attach the specs and standards to an Order or Order item to track the requirements being placed upon a supplier.

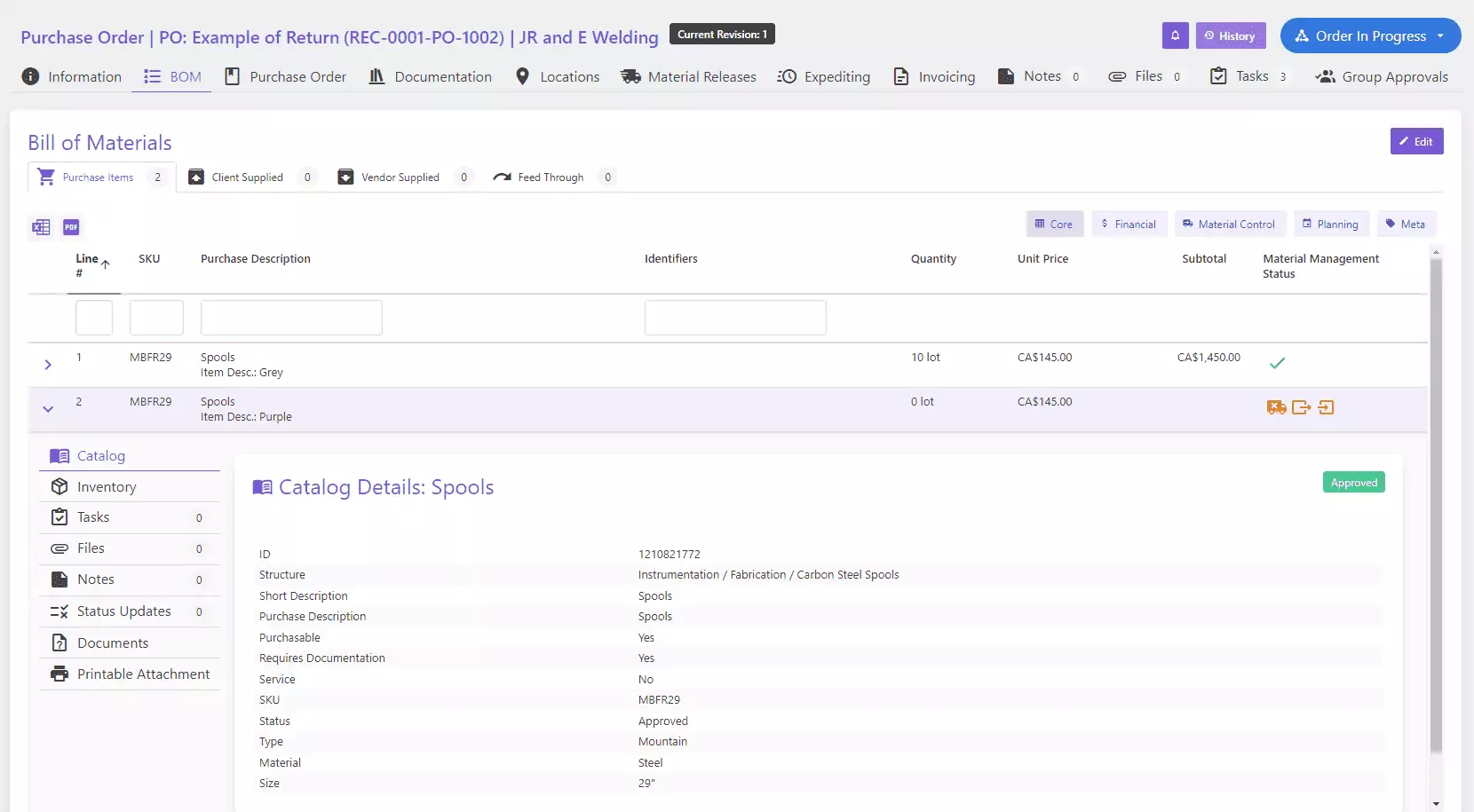

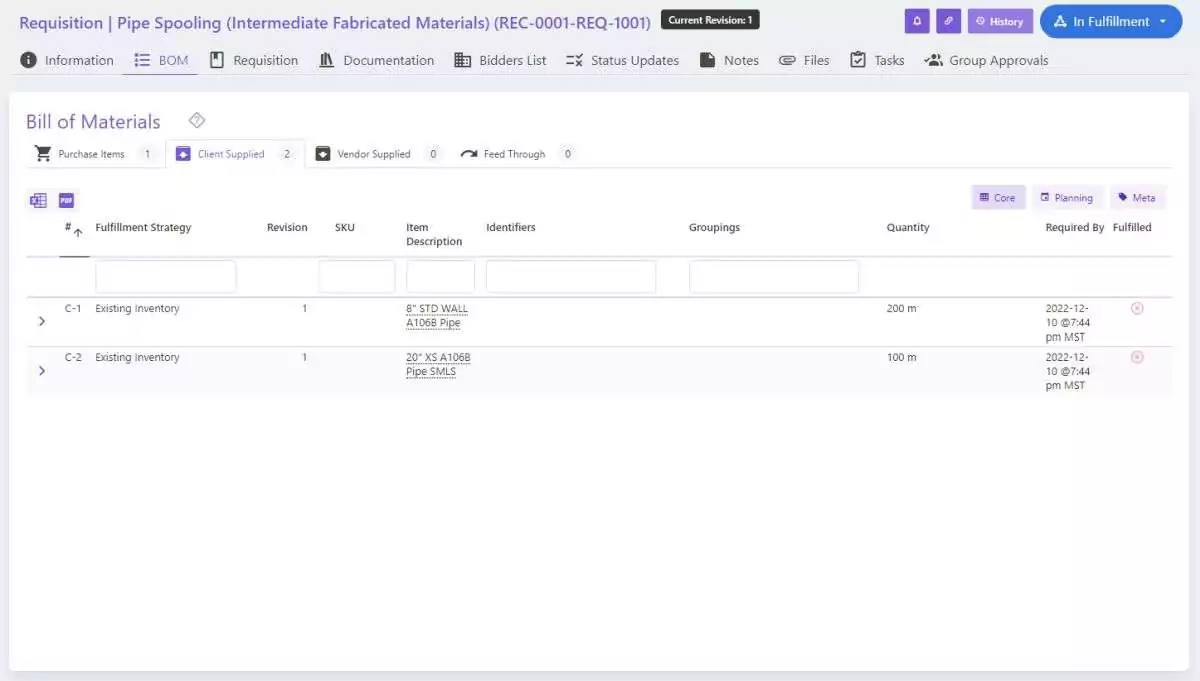

- Cumulative Project BOM (Bill of Materials): While not a requirement, the BOM can create a vital point of control. By defining the complete purchase requirements for a project (which can be modified over the lifecycle of the project), the procurement team can easily track material shortages or overages and proactively address deviations.

- Integrated Vendor Document Requirements: Define document requirements at the Order or Order line-level, including the document type, format, authentication requirements, and dynamic due date. Track Vendor Document Requirements (VDR) compliance by Order or Project.

Create and communicate document requirements, including the document type, format, authentication requirements, and dynamic due date. Define requirements at the order or order line-level.

Create and communicate document requirements, including the document type, format, authentication requirements, and dynamic due date. Define requirements at the order or order line-level.

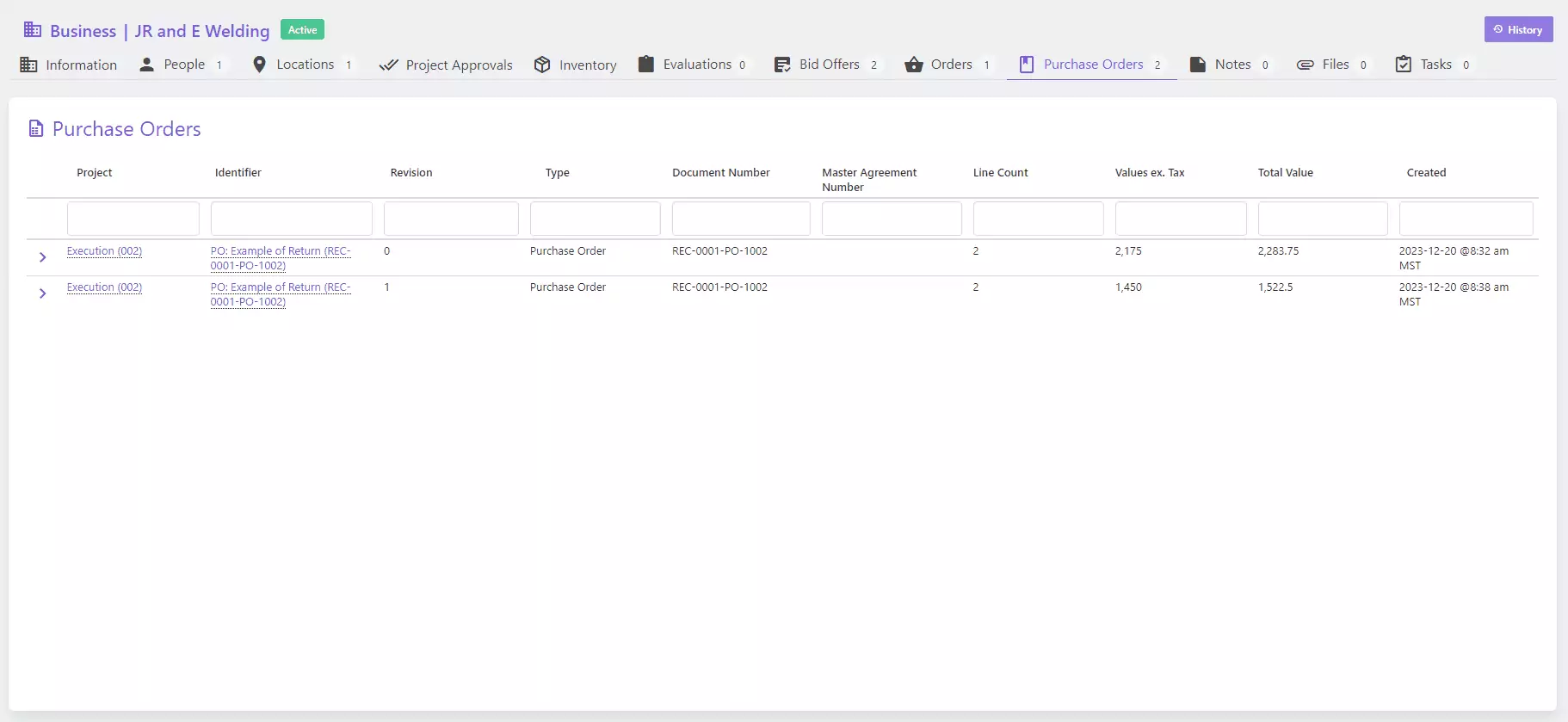

Material Purchasing Management

- Current SCM provides complete and flexible workflow support to efficiently progress Material Requisitions through creation, review, internal approval, client approval, conversion to Bid, Bid issuance, Offer receipt, Offer evaluation, Bid Award, conversion to Purchase Order, tracking, material & document expediting, releasing, receiving, and invoice matching stages.

Perhaps your organization does not require a Requisition or Bid for every Purchase Order? Unlike traditional ERPs that rigidly enforce a linear process of Requisition -> Bid -> Order, Current SCM allows you to begin the process at either the Requisition, Bid or Purchase Order stage.

Intelligent Material Tracking

In addition to real-time Purchase Order line-level status updates, Current SCM provides a variety of tools to help you ensure your materials are where they need to be when they need to be there:

- Utilizes inventory finding to validate upstream materials will be available on the ship date

- Automatically notifies if the upstream material is not available

- Automatically notifies if the upstream material is at risk

- Automatically notifies downstream orders if material is late in arriving

-

Current SCM also supports tracking the origin, usage, and disposition of materials for compliance and quality assurance.

Milestone-Driven Materials Expediting

- Track the overall status of your Purchase Orders with real-time Purchase Order status updates

- Drill-down to track the status of specific items within a Purchase Order with real-time Purchase Order line-level status updates

- Compare status updates against your milestone dates to ensure your materials are on track to be where they need to be when they need to be there

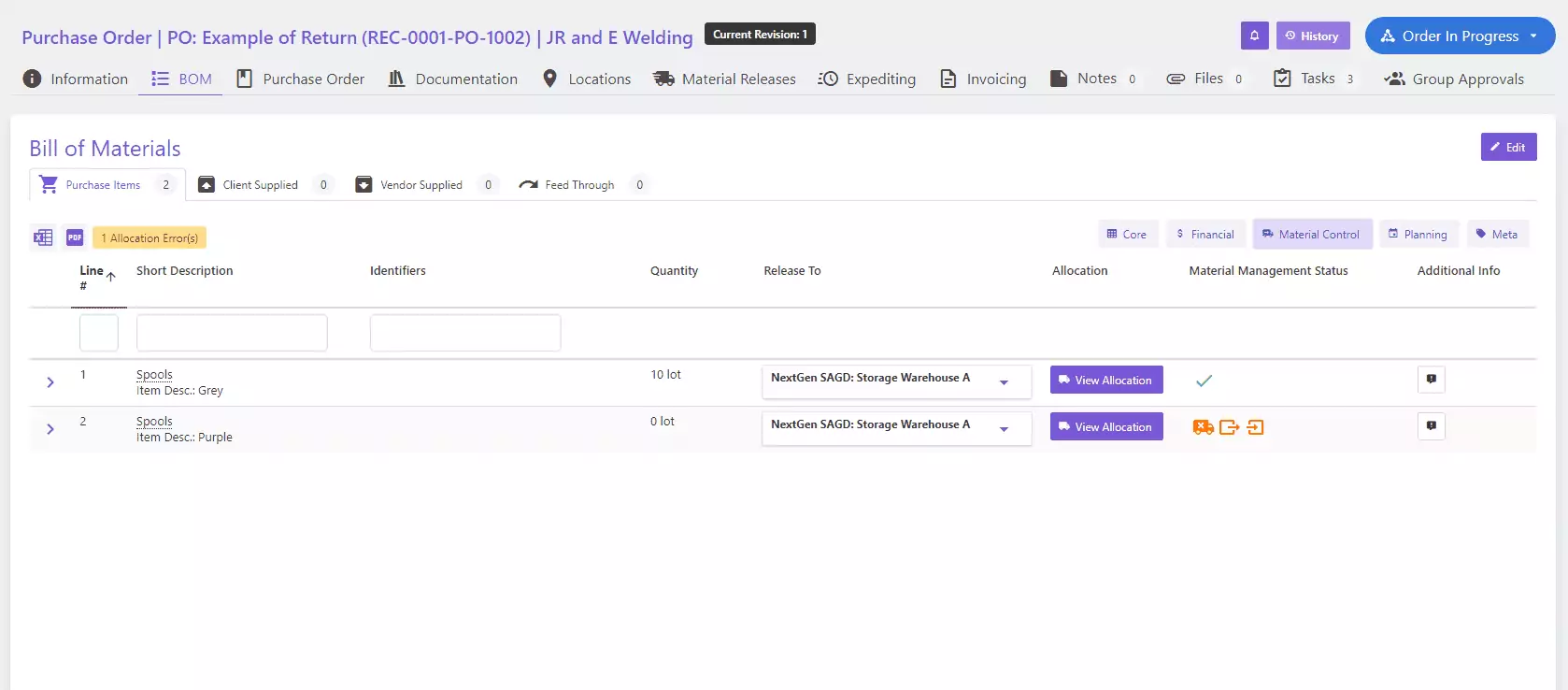

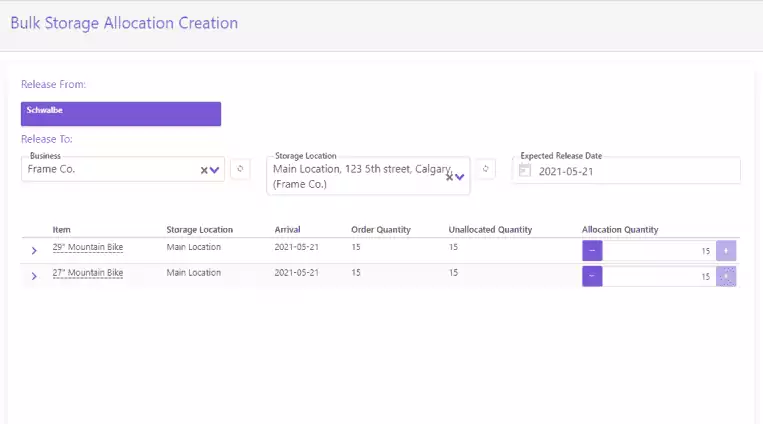

Ensure the Right Material Ships to the Right Location

- Current SCM enables Allocation-based material Releases. By releasing materials based on Allocations, you are tying your inventory requirements to its end use location.Allocations are akin to plans, they tell the software that at a specific time and place materials will be moving to another location. Allocations are executed by issuing and actioning Releases. The software will group like Allocations (same release location and time, going to the same destination) into Potential Releases. Users can convert Potential Releases into an actual Release. Executed Allocations automatically adjust material inventory.

And whether planning for movement, storage, or consumption, Current SCM allows for efficient mass Allocation by line item.

Efficient Material Release Planning

Current SCM provides a cloud-based platform to easily track vendor information, validate Purchase Order status, and generate Releases.

- Save time automating Releases based on predefined Allocations and systemic workflows

- Combine multiple Releases into a single Release

- Generate split-Releases within a single line item

- Add attachments to individual Releases

The software also generates Pre-Release notifications for shipping and receiving parties, as well as Material Receiving Reports (MRR) for receiving party completion.

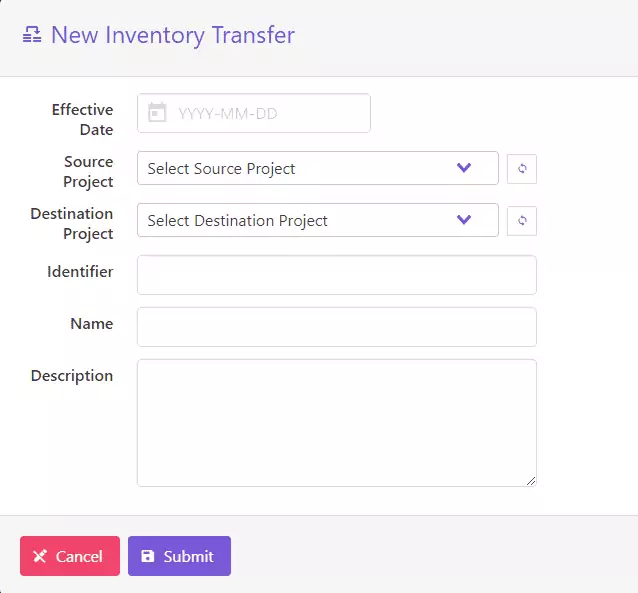

Cross-Project Inventory Visibility & Transfers

Current SCM allows for the option to see and share inventory across all Projects under the same Team. This flexibility offers several benefits:

- For Projects with multiple Buyers, Buyers can ensure they are utilizing existing available inventory

- For Teams purchasing the same materials across multiple Projects, Buyers have the necessary insights to maximize buying power

- For Organizations with a preference for centralized warehousing, materials can be purchased in bulk and allocated to specific Projects as required

- In instances of changing supply requirements or priorities, materials can be transferred between Projects as required

Materials Management Highlights

- Cloud-Based Materials Management Software

- Material Requirements Planning (MRP)

- Specifications and Standard Drawings

- Cumulative Project BOM (Bill of Materials)

- Vendor Document Requirements (VDR)

- Material Requisition Management

- Bid Management

- Purchase Order Management

- Purchase Items

- Client-Supplied Items

- Vendor-Supplied Items

- Feed-Through Items

- IncoTerms

- Storage Allocations

- Transfer Allocations

- Consumption Allocations

- Transfer and Consume Allocations

- Material Tracking

- Tags / Component Identifiers

- Real-Time Purchase Order Status Updates

- Real-Time Purchase Order Line-Level Status Updates

- Upstream Material Shortage Notifications

- Upstream Material At-Risk Notifications

- Downstream Material Delay Notifications

- Materials Expediting

- Vendor Document Expediting

- Milestone-Driven Expediting

- Release Planning

- Allocation-Based Releases

- Configurable Release Order Terms

- Pre-Release Notifications for Shipping & Receiving Parties

- Automated Releases

- Combined Releases

- Split-Releases

- Configurable Receiving Report Terms

- Material Receiving Reports (MRR)

- Inspection Management

- Non-Conformance Reporting

- OS&D Reporting

- Project-Specific Inventory Management

- Cross-Project Inventory Visibility & Transfers

- Central Warehousing Inventory Support

- Items in Transit Report

- Release Order Summary Report

- Project-Specific Asset Management