Expediting in Procurement: An Essential Guide

The fundamentals of expediting in procurement, including the scope, importance of, challenges, best practices, future trends, and more!

Latest Posts

RFP, RFQ, RFT, RFO, RFI, or RFEI? An Essential Guide

Request for X? In procurement, the acronym RFX means Request for X, where X is a variable that stands in for different types of bid invitation...Construction Materials Management: An Essential Guide

While most people identify construction material management with purchasing and distributing construction materials, the reality is more complicated....Spend Under Management: An Essential Guide

Taking Control of Your Spending In today's competitive business landscape, managing your expenses effectively is more important than ever. But with a...

Latest Posts By Category

- Procurement

RFP, RFQ, RFT, RFO, RFI, or RFEI? An Essential Guide

Request for X? In procurement, the acronym RFX means Request for X, where X is a variable that stands in for different types of bid invitation...Spend Under Management: An Essential Guide

Taking Control of Your Spending In today's competitive business landscape, managing your expenses effectively is more important than ever. But with a... - Materials Management

Construction Materials Management: An Essential Guide

While most people identify construction material management with purchasing and distributing construction materials, the reality is more complicated.... - Supply Chain Management

One Size Compliments Most: Current SCM Provides Competitive Advantage to Engineering Firm

Melissa Stockley, a supply chain expert at Vista Projects, has fond memories of the 90s but doesn’t want to be “stuck there.” Stockley spent the... - Commentary

See You at CONEXPO-CON/AGG in Las Vegas?

A quick look at our date wheel reminds us that CONEXPO-CON/AGG is approaching fast! This will be our first time attending the largest construction show... - Expediting

Expediting in Procurement: An Essential Guide

Imagine a smoothly running assembly line, a construction project on schedule, or life-saving medical equipment delivered on time. These achievements all... - Current SCM

Line Level Invoicing and Invoice Attestation for Purchase Orders

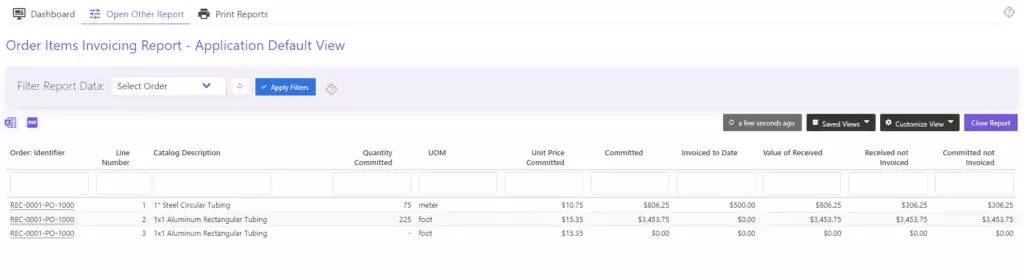

We are excited to announce we have launched enhanced invoicing functionality within Current SCM! The system now supports tracking and cost allocations at...Offer Price Comparison & Historical Purchasing Data

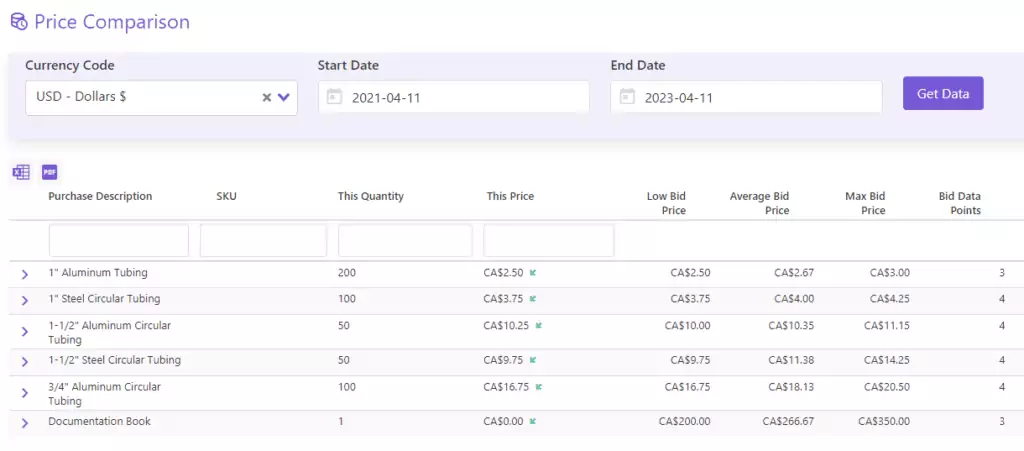

The Data You Need to Make Informed Procurement Decisions We are excited to announce we recently launched two new feature sets into Current SCM. Both...